In today’s fast-paced manufacturing world, maintaining consistent quality control is more crucial than ever. As industries strive to meet the demands of global markets, manufacturers are increasingly turning to advanced technologies like computer vision to uphold high standards. Computer vision, a subset of artificial intelligence (AI), allows machines to “see” and interpret visual data, offering unparalleled precision and efficiency in quality control processes.

This article guides you through the implementation of computer vision for quality control in manufacturing, providing a step-by-step approach and best practices to help you get started.

Understanding Computer Vision in Manufacturing

What is Computer Vision?

Computer vision is a technology that enables machines to interpret and process visual information from the physical world, similar to how humans do. In manufacturing, computer vision systems can be used to inspect products, monitor assembly lines, and detect defects in real-time.

Key Components of a Computer Vision System

A typical computer vision system in manufacturing includes cameras and sensors that capture images or videos, software that processes these visuals, and AI models that analyze the data to make decisions. These components work together to ensure that only products meeting quality standards proceed in the production process.

Common Applications in Manufacturing

Computer vision is widely used in manufacturing for tasks such as defect detection, assembly verification, and dimensional measurement. It ensures that every product meets the required specifications before reaching the customer, reducing waste and improving overall quality.

For more detailed insights and solutions tailored to your manufacturing needs, consider exploring Be Digital’s computer vision solutions for manufacturing.

Why is Computer Vision Important for Quality Control?

Increased Accuracy and Precision

Unlike manual inspections, which can be prone to human error, computer vision systems offer consistent accuracy. They can detect even the smallest defects, ensuring that every product meets the highest quality standards.

Real-Time Monitoring and Cost Efficiency

Computer vision allows for real-time monitoring of production lines, identifying issues as they arise and enabling immediate corrective action. This not only enhances product quality but also reduces costs associated with rework and returns.

Case Studies of Success

For instance, in the automotive industry, companies have successfully implemented computer vision to ensure that each part of a vehicle meets stringent safety and quality standards. Similarly, electronics manufacturers use this technology to detect microscopic defects that could affect product performance.

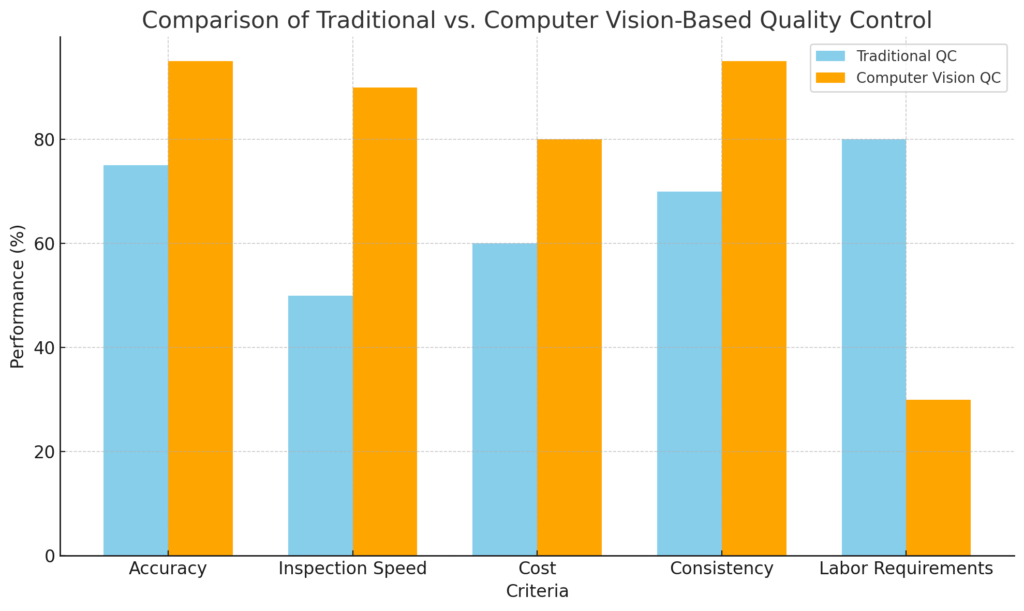

Comparison between traditional quality control methods and computer vision-based systems shows that computer vision significantly enhances accuracy, consistency, and reduces labor requirements, as illustrated in the chart above.

Step-by-Step Guide to Implementing Computer Vision

Step 1: Assess Your Current Quality Control Processes

Begin by evaluating your existing quality control methods. Identify pain points, such as areas where defects are frequently missed or where manual inspections are time-consuming. This assessment will help you set clear objectives for implementing computer vision.

Step 2: Select the Right Technology

Choosing the right computer vision technology is crucial. Consider factors such as the type of defects you need to detect, the speed of your production line, and your budget. You may opt for off-the-shelf solutions or develop a custom system tailored to your specific needs.

Step 3: Develop and Train AI Models

AI models are the brain of a computer vision system. To train these models, you need a large dataset of images labeled with examples of defects. The more accurate your data, the more effective your AI will be in detecting defects.

Step 4: Integrate Computer Vision with Your Manufacturing Systems

Integration is key to ensuring that your computer vision system works seamlessly with your existing manufacturing processes. This might involve connecting the vision system to your ERP (Enterprise Resource Planning) or MES (Manufacturing Execution System) to enable automated decision-making.

Step 5: Validate and Test Your System

Before fully deploying your computer vision system, it’s essential to validate its accuracy through rigorous testing. This phase helps identify any issues and ensures the system is reliable.

Step 6: Continuous Monitoring and Optimization

After implementation, continuous monitoring and optimization are necessary. Use the data generated by the system to refine your AI models and improve the system’s accuracy over time.

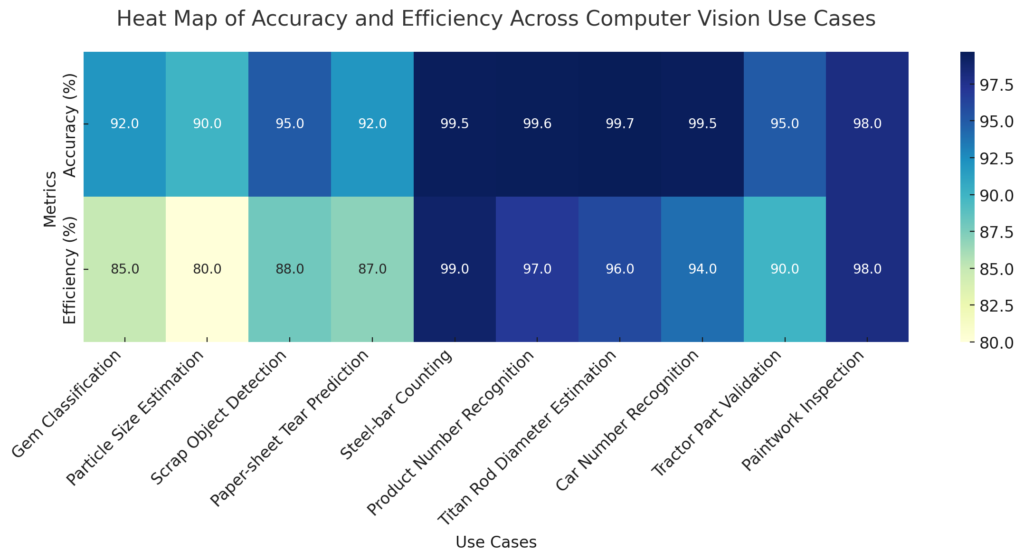

The heat map above highlights the efficiency and accuracy of computer vision across various manufacturing use cases, showcasing the technology’s versatility.

Best Practices for Implementation

Data Management

Effective data management is crucial for training AI models. Ensure that your data is well-labeled and stored securely. High-quality data leads to more accurate AI predictions and better overall system performance.

System Calibration and Maintenance

Regular calibration and maintenance of the hardware components, such as cameras and sensors, are essential to maintain the system’s accuracy. Set up a maintenance schedule to avoid any downtime.

Collaboration with Experts

Implementing computer vision is a complex process that benefits from collaboration with experts in AI and manufacturing. Working with knowledgeable partners can help you avoid common pitfalls and accelerate the implementation process.

Compliance with Industry Standards

Ensure that your computer vision system complies with relevant industry standards and regulations. This is especially important in industries like healthcare and automotive, where quality and safety are paramount.

Overcoming Challenges

High Initial Costs

While the initial investment in computer vision technology can be high, the long-term benefits often outweigh the costs. Focus on the ROI by considering the savings from reduced waste, improved quality, and increased efficiency.

Integration with Existing Systems

Bringing new technology into alignment with existing systems can present significant challenges. To minimize disruption, plan the integration process carefully and test thoroughly before full deployment.

Data Quality and Model Accuracy

The accuracy of your computer vision system depends heavily on the quality of the data used to train it. Invest in high-quality data collection and labeling to ensure your AI models perform well.

Change Management

Introducing new technology requires careful change management. Train your workforce to use the new system effectively and address any concerns they may have about job security or changes in workflow.

Future Trends in Computer Vision for Manufacturing

Emerging Technologies

The future of computer vision in manufacturing is bright, with emerging technologies such as 3D vision and deep learning set to revolutionize the industry. These advancements will allow for even more precise and efficient quality control.

Industry 4.0 and Smart Factories

As Industry 4.0 continues to evolve, computer vision systems will become an integral part of smart factories, where interconnected machines communicate and make decisions autonomously. This shift will further enhance the capabilities of quality control systems.

Predictions for the Future

In the next 5-10 years, we can expect computer vision technology to become more affordable and accessible, making it a standard tool in manufacturing. Innovations will likely focus on improving speed, accuracy, and integration with other AI technologies.

Conclusion

Implementing computer vision for quality control in manufacturing is a game-changer. By following the steps outlined in this article, you can enhance the accuracy and efficiency of your quality control processes, reduce costs, and stay ahead in the competitive manufacturing landscape. As technology continues to advance, now is the perfect time to explore how computer vision can transform your operations.

For manufacturers looking to remain competitive and improve product quality, investing in computer vision technology is a strategic move that promises significant returns.

Explore AI-powered solutions here and discover how Be Digital can give you a competitive edge.

Join our growing community!

Follow us on LinkedIn, X, and Facebook to stay updated on the latest AI trends, insights, and success stories.